The Last Puff of Steam - Rudolf Diesel's Most Clever Creation, Part 2

Rudolf Diesel's Final Triumph

July 21, 1959, 7:55 p.m., Cheyenne, Wyoming. That’s the moment Rudolf Diesel’s machine finally slew the the last, mighty Steam Engine, the moment that the Union Pacific’s Big Boy No. 4015, then barely 15 years old, pulled into the yard. It was the steam engine’s last commercial run. The economic efficiency of the heavy and slow Diesel-Electric locomotive could no longer be denied. Rudolph Diesel’s most clever creation finally won.

“The final season of service for the Big Boys was July 6 -21, 1959 when the 4011, 4014, 4015, 4017, 4019 and 4023 made 45 round trips between Cheyenne and Laramie. It ended with the 4015 arriving in Cheyenne at 7:55 p.m. on July 21.”

The Big Legacy of the Union Pacific Big Boy, James J. Reisdorff and Michael M. Bartels, South Platte Press, April 2006.

If you go to Union Station in Ogden, Utah, you will find Union Pacific’s Big Boy 4014. It last ran on the main line in 2019. I took my grandson to see it a few months ago and had a conversation with the volunteer conservator. The ballast around the track was getting pretty thin and I suggested that he could get more from Nucor Steel’s plant in Plymouth, Utah. It would match the existing ballast quite well and shouldn’t cost much. Nucor makes a lot of steel and produces a lot of slag.

Parked right next to Big Boy 4014 is another UP locomotive—one of the early diesel-electric models—I don’t recall its number. If you talk to the old engineers—I have quite a bit over the years—they’ll tell you what a shame it was to see the steam locomotives retire. You see, the steam locomotives were superior to the diesel-electric in almost every way but one. Most of all, the steam engines were like stallions, light, limber, and fast. They easily reached breakneck speeds and were exciting to run, while the heavy, cumbersome diesel-electric was, well, slow. And heavy. And boring. And heavy.

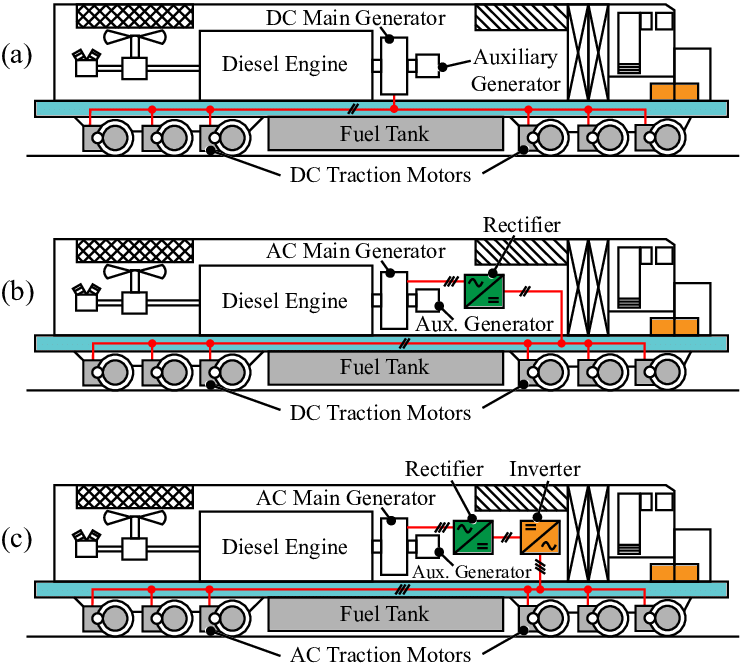

Before the 1940s, nobody could have even imagined the demise of the Steam Locomotive for hauling freight. If you like the history of technology, A History of Union Pacific Dieselization, 1934-1982 is worth reading. Long story short, the diesel-electric engine is rather complex but its biggest problem is that it’s heavy. It has several different combinations of engines and motors: Diesel Generator; AC and DC Electric Generators; Electric Motors; and various other gadgets and gizmos.

One common element is the Fuel Tank. That holds Diesel Fuel, and for good reason. It’s called energy density. More on that later.

By contrast, the Big Boy was nothing more than a giant boiler, with thousands of tubes for heat exchange. Despite its size, it was surprisingly light and powerful, packing a whopping 7,000 horsepower when fully up to steam and designed to run 70 miles per hour.

If freight needed to be delivered fast, the Big Boy was the way to do it. It took until 1969 to match this performance with the Centennial class of engines. They stretched more than 98 feet, packed 6,600 horsepower, weigh 270 tons, and ran as fast as 90 miles an hour. They were built only for Union Pacific Railroad. The name "Centennial" was selected to commemorate the 100th anniversary of the driving of the Golden Spike on May 10, 1869.

The triumph of Rudolph Diesel’s invention over the Steam Engine can be reduced to two words: Thermal Efficiency (aka Engine Efficiency).

Rudolph Diesel’s engine has the highest thermal efficiency (engine efficiency) of any practical internal or external combustion engine due to its very high expansion ratio and inherent lean burn which enables heat dissipation by the excess air.

Diesel’s efficiencies are manifold, wrapped up into a single engine. For one thing, the engine uses heavy oil fuel. This allows for the fuel to be injected into the air in a controlled way by manipulating the air-fuel ratio (λ); instead of throttling the intake air, the diesel engine relies on altering the amount of fuel that is injected, and the air-fuel ratio is usually high.

Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites.

The absurdity of the idea that battery-power can, will, or should replace Rudolph Diesel’s engine should be self-evident. But alas it is not, except to a few people who understand objective reality.

The idea hardly warrants much analysis. Let’s just focus on the Diesel Fuel tank present on every diesel-electric locomotive. The liquid fuel in that tank has orders of magnitude more energy density than any battery could possibly hold. And charging and charging. And with every charge, it holds less. And less. Till it requires replacing. And replacing.

Civilization's entire industrial and agricultural base is 100% dependent on "heavy distillates" (diesel-kerosene-jet fuel-tar-bunker-heating). This is because of the magnificence of the Diesel Engine. Imagine a world without:

Farming equipment

Locomotives - trains

Mining equipment

Long-haul trucks

Construction equipment

Diesel generators

Drilling equipment

Well, we should not be imagining any such world. But we should be imagining a world where humanity obtains low-cost Diesel Fuel through Nuclear Power-based synfuels from feedstocks other than Crude Oil. For more on this, see Crude Oil is Like Raw Milk and Diesel Fuel is the Cream.

If you pay attention to any serious rail advocate (no matter how "green" their proclivities) you will see that electric rolling stock is vastly superior, but only catenary fed. Battery-Electric rail is a fairly useless dead end, mainly desired by US planners who have no interest in learning best practices from other places.

No doubt the diesel engine will continue to be very useful in a large number of situations where electrification is impractical, and synfuels are an excellent way forward in this regard (even using solar - look at what Terraform Industries is up to). But mainline rail need not be primarily diesel.

Well, they use electric trains a lot in Europe. Most of Russia, including long routes all the way to Siberia use electric trains and an overhead catenary. The only justification for that is the fuel economy of electricity vs diesel fuel. That complex system just could not compete with a battery locomotive with current battery prices and energy density. You would be far better off to use battery locomotives with fast charge stations at train stations. Could be wireless charging also. A battery locomotive may make more sense than a battery light vehicle since the locomotive will optimize the economics of electric charging. I can't see diesel city buses, LRTs or trolley buses competing with battery electric. Of course the way they are pushing up the price of electricity with wind & solar scam energy vs how much they are pushing up the price of diesel fuel leaves considerable uncertainty in the future economics.

In the meantime the series hybrid diesel or methanol locomotive would be the obvious choice. Methanol being much cheaper than diesel, and an optimized methanol engine being much smaller, lighter, more efficient and much cleaner exhaust than a diesel. The methanol engine would run continuously at the most efficient speed charging the batteries which would also store downhill and stopping energy for acceleration and hill climbing.